Foam Lamination Process

-

Foam lamination alters the density, stability, and makeup of the foam product. Substrates used in this polyurethane manufacturing process can be a film, non-woven, fabric, or even another foam.

-

ABOUT THE FOAM LAMINATION PROCESS

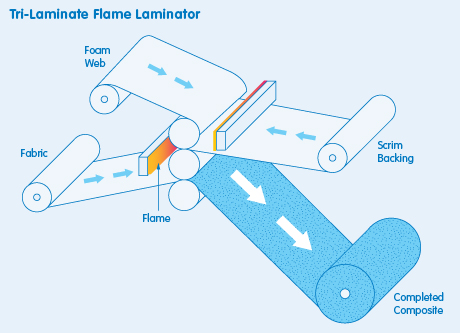

The lamination of foam to different substrates is either achieved using either adhesive lamination or flame lamination.

In adhesive foam lamination, as the name implies, adhesives are used to attach the foam to the substrate.

In flame foam lamination a flame front is used to attach the foam to the substrate. One example of flame laminated foam would be the lamination of foam to a fabric substrate in the production of headliners for automobiles.

In either case, foams can be attached to substrates to form bi- or tri-laminates.

USES OF LAMINATED FOAM

Foam lamination alters the density, stability, and makeup of the foam product. Substrates used in this polyurethane manufacturing process can be a film, non-woven, fabric, or even another foam.

• Laminated foam can be used to customize sound barrier

• Foam to foam lamination

• Foam lamination to provide heat resistance

• Laminated foam can ensure containment of liquids and gases -

- Resources

- PRODUCTS

-