Foam Coating Process

-

Different foam coatings perform different functions with regards to surface properties when applied following the polyurethane manufacturing process.

-

FXI'S FOAM COATING PROCESS

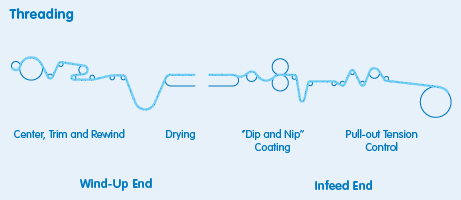

FXI foams can be coated using a "dip and nip" coating process to apply a coating to the foam. Foam coating can include: latex, PVC, acrylics, vinyl, activated carbon, conductive carbon, etc.

USES OF FOAM COATING

Different foam coatings perform different functions with regards to surface properties when applied following the polyurethane manufacturing process.

• Foam coating can deliver certain melting properties for heat seal applications

• Certain foam coating offers adhesive properties for vacuum seal applications

• For certain applications, foam coating can provide low surface energy (as for a non-stick surface)

• Some foam coating can create desired electronic properties (such as passivity and conduction)

• Ensure water-resistant or water-proof properties with foam coating -

- Resources

- Functions Info (PDF)

-